Einblicke / Insights

01

Fly.Bot

The initial hype surrounding the use of drones in logistics has faded. After the first pilot operations, it has given way to realistic pragmatism - there is currently little sign of delivery logistics being turned upside down by the drone. Even though the Gartner Hype Cycle predicts that the drone will only reach the peak of its exaggerated expectations in the future, the reality of logistics is that the drone has already passed through the valley of tears with regard to the expectations placed on it and realistic assessments of possible drone applications in logistics are now pending.

please scroll down to read more ...

02

Smart logistics 4.0

Autonomous robots for smart warehouse automation, AI-assisted cameras for container recognition and tracking without any human intervention, and digital twins for the physical warehouse or the planning supply chain show the departure into a digital logistics world. We look at 12 key action areas that are driving the paradigm shift to Logistics 4.0.

please scroll down to read more ...

03

coming soon

...

03

04

05

06

07

08

09

10

11

Fly.Bot

Fly.Bot

When will you get your pizza delivered by drone?

A status on the use of drones in logistics

By Dr. Wolfgang Keplinger, ECCELL GmbH

The initial hype surrounding the use of drones in logistics has faded. After the first pilot operations, it has given way to realistic pragmatism - there is currently little sign of delivery logistics being turned upside down by the drone. Even though the Gartner Hype Cycle predicts that the drone will only reach the peak of its exaggerated expectations in the future, the reality of logistics is that the drone has already passed through the valley of tears with regard to the expectations placed on it and realistic assessments of possible drone applications in logistics are now pending.

Three different areas of use for drones in logistics have emerged. One for transporting information, two for transporting physical loads.

- Drones for the extraction and transport of information.

The inspection and monitoring of large outdoor facilities such as bridges, power lines, wind farms or photovoltaic plants is the most widely realized application of drones outside of logistics. More logistics-related but similar drone applications for the extraction of information are the external visual inspection of large aircraft, the monitoring of production plants with regard to the inflow of trucks or of port facilities via the inflow of ships. In the latter applications, however, the drone competes with GPS-based localization solutions in combination with geo-fencing.

In logistics itself, the most widespread drone application at present is that for the automatic recording of inventories or for inventory creation, predominantly in manual pallet warehouses. The providers of corresponding systems see the advantage of these logistics drones in the generation of current and correct inventories, as well as in the simpler, safer, more correct and more efficient recording of this inventory data. The main applications for this are found in warehouses in the food and chemical industries, as well as in fast-moving warehouses. However, this application must be countered by the fact that drone-assisted inventory serves to conceal weaknesses in the existing process (namely the lack of knowledge of which material is currently stored in which place) by means of an efficient, technically digitized solution. In the spirit of a lean paradigm that also applies to digitization, however, only processes that are efficient, waste-free and robust should be digitized.

Three technologically different types of inventory drone are offered on the market:

- Inventory drones flown manually by a human pilot

- Drones flying autonomously

- "Follow-me" drones that follow a ground-guided autonomous rover

The future, of course, belongs to the two autonomous solution directions. The advantage of rover-based drones lies in the simpler navigation software for the drone (the AMR rover takes over the navigation in the x/y axis) but above all in a significantly longer flight time. Because the drone is connected to the rover via a cable, a much more powerful and thus heavier battery can be integrated into the rover, which increases the flight time of a drone with one battery charge tenfold from 0.5h to 5.0h. However, autonomous flying drones with a charging station with multiple batteries and autonomous battery replacement will also make progress in this regard. If the current areas of application of the inventory drones are aimed primarily at the non-operational times in a warehouse (night/weekend), in the future the autonomous drones will also have no restrictions on simultaneous operation with the (autonomous) mobile warehouse equipment. However, for the accuracy of the inventory creation itself, it is not a disadvantage to perform it in the non-operational warehouse time.

The drone as a technological tool to be able to reach all storage bins easily and without much additional effort is, however, only one aspect of this solution. Another important technological component lies in an AI-assisted camera for label recognition, a camera for taking photos of the labels, software for reading the label information, and an LED light for illuminating the camera area, since the drones are also used during non-operational (and thus unlit) storage time. I.e., the novelty character of this technological solution lies not only in the drone as a flying device, but also in the autonomous control of the drone and/or the rover and, above all, in the AI-based computer vision that recognizes and can read and store labels or containers/pallets. The leading provider of these solutions in Germany is Doks. However, inventory drones can also be obtained from Linde, Eyesee, Corvus, Ware, Flytware and other suppliers.

With these technologies (AI-based computer vision), a described drone system can also be used for counting (empty) containers, i.e., for warehouse areas where there is usually no booking of incoming and outgoing containers. This can happen in connection with a drone flying over the storage area (both inside a storage building or outside/outdoor storage area) or without drones by fixed mounted ki-supported camera systems on the building ceiling.

2. Drones for intralogistics transport

Another important area of application for logistics drones is in the intralogistics sector for the transport of physical goods. Here, the drones will not take over the transport of large material flows/volumes, but will be used in a well-selected spot-to-spot transport area. The large mass flows will continue to run on the ground in the future.

The drone operations tested in pilot applications or in continuous use in this regard are used

§ In large-scale production plants to transport urgent express deliveries of defective parts on the line in order to avoid production interruption or line stoppage

- to link external logistics hubs with production plants (also for express deliveries, as Seat does at its plant in Martorell, for example)

- the connection of decentralized units with a central laboratory equipped with high-end equipment (e.g., at ThyssenKrupp, where 4 blast furnaces were connected to the central laboratory via a drone)

- the connection of operating theaters with a central laboratory if the latter is spatially distanced

All intralogistics transport applications have one thing in common: they transport individual products or samples that are not too large and not too heavy and that are needed quickly at a more distant location. In doing so, the drones usually fly no further than 5 km, no longer than 0.5h and no faster than 50 km/h. The advantage of many of these intralogistics solutions is that they are usually flown over private company grounds; public areas are not affected, which facilitates the sometimes lengthy, expensive and often not yet regulated acquisition of flight licenses. Dealing with the problem areas of logistics drones, their noise and ensuring the safety of transport, is also easier to clarify and regulate on private property than for drones flying in public space.

3. Last Mile Delivery

The third major area of application for drones is in the delivery of (e-commerce) shipments over the last mile. Here, all major logistics providers such as Amazon, UPS, DHL, FedEx and others have had their first pilot experiences with drones. Three useful areas of application have emerged:

1. supplying generally sparsely populated areas that are difficult to reach, such as islands or mountainous regions.

2. supplying densely populated urban areas from urban logistics hubs to be faster than traditional delivery by parcel truck (0.5h - 2.0h delivery)

3. drones brought to the delivery region by parcel truck, then assisting the driver in covering the very last mile

Technologically, the main issues for small parcel drones have largely been resolved. Current development has now reached the point where Volocopter is working on an all-electric drone that can transport a pallet weighing up to 200 kg over 40 km.

Delivery over and into sparsely populated areas is not only affected by permits, but also by the question of economic viability. The biggest problem with using drones for last-mile delivery in densely populated areas at this time is

- The acceptance by the general population (noise and safety) and especially

- The lack of regulations on the operation of drones in public areas.

Switzerland is considered a driver of innovation in this area and plays a pioneering role in Europe. Since 2017, the Swiss Federal Office of Civil Aviation and Skyguide have been working together to test regulated drone traffic in public areas. Issues such as flight altitudes, safety, control, blocked and permitted corridors or entry lanes/drone highways for reaching major cities are being discussed and clarified. Regulations, safety in public spaces and noise caused by drones are the biggest hurdles to making last mile delivery by drones a breakthrough. These hurdles are currently so great in Europe that delivery by drones will not become a standard offering of logistics service providers or parcel and express service providers in the next few years. In the next few years, you will get your pizza delivered faster and faster and with a high probability still warm. However, the probability that it will be delivered to your home by drone is very low for the next few years.

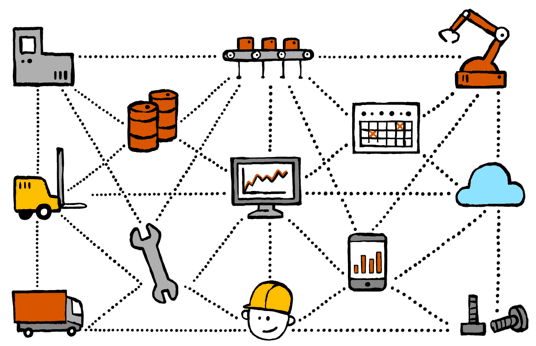

Smart Logistics 4.0. 12 fields of action

By Dr. Wolfgang Keplinger, ECCELL GmbH

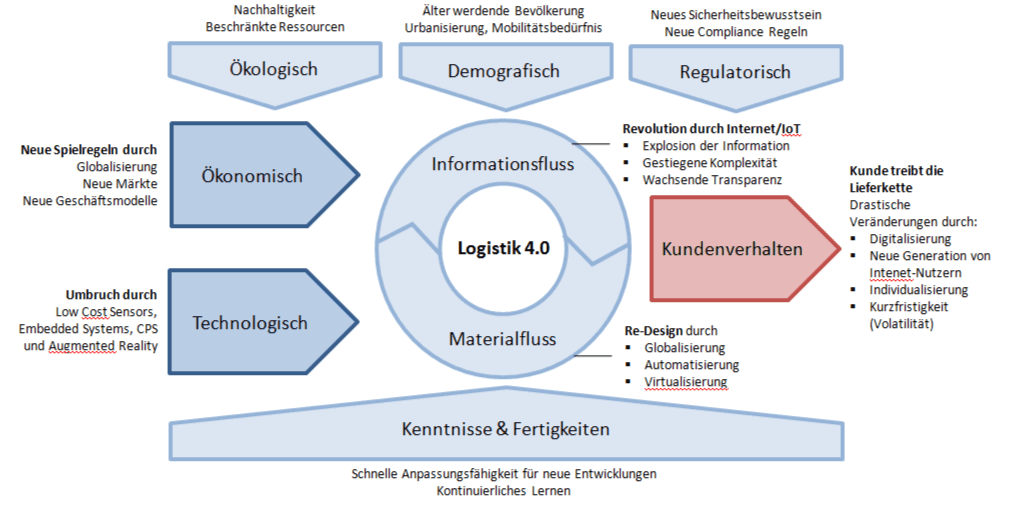

Autonomous robots for smart warehouse automation, AI-assisted cameras for container recognition and tracking without any human intervention, and digital twins for the physical warehouse or the planning supply chain show the departure into a digital logistics world. We look at 12 key action areas that are driving the paradigm shift to Logistics 4.0.

1. I, LOGISTICS-ROBOT

Smart productivity booster @ zero-defects

In the past, you either had a manual warehouse or a very rigidly automated warehouse with expensive, heavy stacker cranes. Intelligent warehouse automation with smart and flexible warehouse robots is one of the most significant current trends in logistics. Smart automation options in the warehouse include:

- Automated shuttle warehouses with many small robots/shuttles instead of the large, heavy and less flexible stacker cranes.

- Pick buddies, (e.g. from Locus, Geek+ or 6River Systems) that pick up manually picked goods from the picker and bring them to the shipping department

- Shelf buddies, (e.g. from Amazon or Swisslog) that bring entire shelves to the pick station, where they are then picked manually

- Conceptually completely new, smart automated warehouse types such as

-

Autostore, which does not require racking and achieves enormous

storage density by directly stacking totes

- Servus, a shuttle system where the robots travel on rails to the

production area and transfer the picked totes directly to the assembly

line.

-

Exotec, a shuttle system in which the shuttles independently take over

the vertical movement (climbing on the rack), but otherwise move freely

and autonomously

- Autonomous picking robots (e.g., from Magazino or identytec), which autonomously pick or move the material/containers into the storage bin

- Cobots that unstack, sort, empty and queue picks or bins

- Autonomous Mobile Robots (AMRs) that move independently and autonomously in the warehouse alongside the employees working there and transport and move material and containers as underride/stacking/KLT-FTFs

- Autonomous tugger trains (e.g. from Schiller, Linde or Asti) for transport on routes with high transport volume

All robot-based solutions are characterized by significantly increased productivity and extensive freedom from errors. At the same time, the systems are intelligent, partially autonomous, collaborative, flexible and agile, scalable, electric, energy-efficient and plug&play. They help to relieve employees of heavy, unergonomic handling activities and in many cases take over those work steps that are tedious, difficult or not really value-adding from a lean point of view (e.g. long transport routes).

2. FINALLY HANDS-FREE

Wearables liberate employees

The now almost traditional scanner in logistics helps employees to clearly identify material and securely document material movements (e.g. putting into a storage bin / picking from a storage bin). But the traditional handheld scanner keeps employees busy searching for where the scanner is or grabbing/putting the scanner away. Thus, the scanner sequentially drags out the work sequences because the employee is either busy with the scanner or walking/driving through the warehouse.

The major benefit that Logistics 4.0 has brought to manual workplaces is to free up employees' hands again for the primary value-adding logistics activities: for handling materials or driving forklifts or tugger trains. Freely following the motto: "automate it or wear it," all logistics work that cannot be economically automated, and thus remain manual, should be supported by wearables. These wearables (X-by technologies, gloves, rings) are the technological solution to make information communication or confirmation independent of the hands, so that they are available for the core activities of manual logistics: Handling and steering. And this makes the processes more streamlined, because the information message or confirmation is integrated into the core value-adding steps.

Currently, the most important wearables that enable employees to work hands-free/bi-manually and thus ergonomically and productively are pick-by-voice, pick-by-vision/smart glasses, forklift fork scanners, scanner/RFID gloves, data watches, and NFC and smart motion rings that support access control, quality control, and execution confirmation control.

The wearables increase the productivity of the employees who wear them. But what is at least as important: they improve the ergonomics of the employees and they reduce errors.

3. NO-TOUCH-LOGISTICS

Any additional step would be waste

One of the biggest effort but also time drivers in logistics is the number of necessary handling steps, i.e. how often a tote/pallet/carton is handled, picked up, set down, moved, put into storage, retrieved, stacked or retrieved. With regard to low-handling no-touch inbound logistics, the following alternatives are available (starting with the leanest alternative):

- Warehouse on Wheels (WoW): The materials are staged directly in the trailer/swap body near the location where the materials are to be installed and are only removed from the trailer/swap body and installed immediately when required. WoW is usually applied for large-volume fast-moving items that are planned and staged in a JIT/JIS mode, because there is no logistical goods receipt control in this staging mode.

- Decentralized goods receipt / ship-to-line: Here, the materials are delivered decentrally, i.e. close to the line, are unloaded and are then available in the form of small buffers with a short range (a few hours) directly at the shoring location. This staging is also primarily used for fast-moving materials in JIT/JIS mode, but has one more handling step than WoW due to the immediate unloading from the truck. In return, fewer gates are needed and trucks can usually deliver more than one material.

- Central Goods Receiving / ship-to-stock: Here, materials are traditionally delivered to a central goods receiving department, with the usual checks regarding correct material number in the correct quantity, in the correct container and label, delivered undamaged. This process is suitable for all medium- and slow-moving materials. Ship-to-stock, however, requires additional handling steps through storage in the central warehouse (i.e., storage remote from production/assembly line) and provision as needed on the line or in the supermarket by logistics.

4. DATA | DATA | DATA

Transformational power of data driven insights

The current starting points of Big Data Analytics are

- Finding correlations that have not been found before. Modern graphical analysis tools (graph analytics, e.g. from Tableau, Y42, Visplore, ...), which allow intuitive work with large amounts of data, help here. For example, to establish a connection between plants in the market, plant failures and required spare parts and thus ensure the availability of spare parts in the right region in time.

- Correctly predicting demands and necessary capacities. Just as Amazon does and extrapolates future demand from the sales of comparison/reference products, test regions or the behavior of certain customer groups/clusters and then places the individual items in advance in a quantity to meet demand in the individual customer fulfillment centers. Long before actual customer demand arises or even customer orders are received.

- Real-time simulation and optimization of supply chains. For example, Spain/USA-based startup Factic offers a SaaS platform that provides predictive analytics solutions for the food and beverage industry. It does this by using data mining and AI techniques to analyze data from internal and external sources and predict future sales. Data-driven decisions are derived from the predicted demand variances to automate procurement. Or Flexport, a San Francisco startup, uses cloud-based, real-time analysis of material volumes from importers, exporters, freight forwarders, airlines, shipping lines, ports, airports, and customs expected at individual ports/airports/logistics hubs. This controls which nodes shipments should be sent through to get into the country and to customers as quickly as possible.

5. AS TO YOUR NEED

Marketplaces for everything

The underlying logistics trend is "elastic logistics," which enables companies to make their supply chains more efficient in times of fluctuating demand. This is achieved by increasing or decreasing the size of the logistics network in line with demand. In other words, the company's own formerly fixed assets are replaced by logistics services that can be purchased or returned on the market at short notice.

The basis for elastic logistics are marketplaces for transports, warehouses or the last mile. The

transport marketplaces bring together the demand for transport capacity and the supply of forwarders at short notice. These marketplaces have existed for a long time, they exist for truck full loads, for LTL transports but also for general cargo. The newer

warehouse marketplaces

do the same in the area of storage space and bring together supply and demand there flexibly and at short notice. Some well-known warehouse marketplaces are Flexe, Stowga, Stord, Hive, storingcargo or log-hub. And finally, the

last mile marketplaces, which are therefore of great importance because they represent one of the largest single cost blocks (usually at least one third of the total delivery costs). For example, Walmart in the U.S. is currently working on a pilot with a last-mile marketplace to deliver express deliveries in a timely manner. Amazon has announced the Amazon Flex platform, which relies on "on-demand service providers" to accelerate the expansion of its Prime One Day delivery program.

6. CLAIRVOYANCE

Knowing your materials – anytime, anywhere

Through the sensor-based connection of objects/items/consignments with the Internet (IoT), we know practically everything about the condition of these connected consignments in real time: in addition to the location, we either know the quality of the incoming consignment in detail, or we can intervene in time before qualitative damage (e.g. due to heat) happens. Here, the latest generation of microscopic sensors (e.g., from RVMagnetics) can help to accurately detect and track this logistical condition. The applications for IoT-connected logistics sensors are now manifold: they help logistics buildings manage climate better, more effectively, and more "green/sustainably." IoT systems for fleet management (e.g. Fleetroot) optimize the use of vehicles in logistics fleets. Or real-time monitoring systems for containers (e.g., the one from IoT startup Globe Tracker) help track or find them more easily.

One example is the service offerings of Roambee, a company that provides a supply chain monitoring system consisting of sensors connected via IoT to a platform or control tower to monitor and track the location, security and condition of materials in the supply chain. And this is flexible on demand, i.e. as Logistics-as-a-Service. Without investments for the user.

This increasingly fine-tuned and real-time-based tracking of individual shipments will increasingly transform the currently rather reactive tracking & tracing into a proactive management of the expected time of arrival (ETA). This means that the backward-looking question of "where is my material currently en route?" will increasingly give way to the question of "when will my material arrive?" and "what do I have to do, if necessary, to be able to meet customer expectations as planned despite deviations from the planned inflow?

7. SUPER-MODELS

A virtual representation of everything

Digital twins are a unique virtual representation of a potential or physical object or process. In logistics, there are now digital twins for warehouses/distribution centers. These are 3D models of an actual warehouse so that capacity utilization and storage locations can be optimized, volume/material flows can be simulated for daily operations and bottlenecks can be avoided, or shift and working times can be adjusted to achieve the best possible performance and customer service. dm received the German Logistics Award in 2020 for its new distribution center in Wustermark. Based on digital twins for all stores supplied, the distribution center packs the goods for each store in such a way that the store-specific shelf stocking process can be carried out with as little effort as possible. In other words, the distribution center takes into account which materials are next to each other on the shelf in a specific store when creating the colli.

Logistics twins are also available for entire supply chains. In this case, the supply chain is mapped in a digital twin from the supplier through the individual delivery stages or across the logistics service providers. These digital twins are then used to optimize the planning and controlling processes of logistics. These twins are used, for example, in the Control Tower to control the supply chains. It is recognized how bottlenecks affect the supply chain or which improvement measures are necessary to keep the impact on customer delivery service as low as possible or to prevent the costs for express transports from exploding.

8. PROGRAMED KNOWLEDGE BOOSTER

As if by magic

AI (artificial intelligence) is now firmly established in core areas of logistics, leading to significant improvements in efficiency, quality and productivity. Core application areas of AI in logistics include:

- Predictive demand forecasting - in the area of logistics planning, as a basis for future customer requirements, as input for S&OP processes. The reliable detection and prediction of customer needs long before they actually materialize is the basis for robust supply chains with a high level of customer service. New Zealand start-up Insite, for example, offers AI-based software solutions for price prediction, demand forecasting, and optimization of operations and processes, primarily in the consumer goods and retail industries.

- Route optimization - both in the last mile of delivery and for AMRs in the warehouse or on the factory floor. Australian startup Adiona is developing AI-based optimization software-as-a-service (OSaaS) that enables companies to improve their logistics processes and reduce costs by optimizing delivery routes statically and dynamically.

- Process automation based on intelligent recognition of handwritten forms (AI-based OCR recognition). This can significantly simplify, standardize and accelerate many manual paper/form processes in international supply chains.

- Visual image recognition - AI-enabled smart cameras recognize containers, labels, people, machines, forklifts and display them with ever greater accuracy and reliability. This enables AMRs to find their routes independently, even if they or the obstacles in the routes change dynamically. Other applications support the rapid and reliable counting of materials in containers, the recognition of labels in the course of drone-supported inventory, the detection of containers in the empties warehouse or screen-guided and controlled packing processes.

9. LOST DRIVER

Who controls in the background?

The experts distinguish between the categories of assisted driving, automated driving and autonomous driving. The current development status in Germany is just reaching level 3 - automated driving. This means that the first vehicles (e.g. Audi A8, Daimler S-Class) for highly automated, autonomous driving on highways at speeds below 60 km/h and in traffic jam situations will be completely handed over to the driving computer; the driver will then no longer have any control duties. In the field of logistics, there are three main areas of application for autonomous driving:

- Driverless trucks - TuSimple, an American startup, specializes in technologically equipping trucks for autonomous driving. The company is currently leading the way with its Level 4 capabilities for the U.S., in which the vehicle handles certain highway sections completely autonomously and the driver can completely relinquish control of the vehicle.

In Europe, Swedish company Einride offers a driverless truck. Its futuristic vehicle design without a driver's cab attracts attention during the first journeys on public roads between two logistics hubs from application partner DB Schenker. - Autonomous vehicles for intralogistics - here the development has taken place in recent years from AGVs (Automated Guided Vehicles - contactless guided vehicles), which were on the road on more or less fixed routes independently of guidance technology, to AMRs (Autonomous Mobile Robots), which are truly autonomous on the road, freely choose the route and can also avoid obstacles without any problems.

- Delivery rovers for the last mile - these autonomous robots drive on public roads and especially also on sidewalks and take over the home delivery of e-commerce orders or in many cases also the delivery of food orders from restaurants.

10.

EVERYTHING AUTOMATED

Process automation not only physically in the warehouse

With the new blockchain technology and RPA (Robotic Process Automation), technologies are now available that also enable automation of previously manual/back-office processes. The blockchain-based smart contracts allow the automatic execution of process steps if certain conditions are met. The advantage of these smart contracts also lies in the fact that these conditions do not necessarily have to be met on site, but the processes can also be triggered remotely. This makes blockchain technology suitable for automating the information/paper flow in supply chains. Payments can be triggered or a transfer of ownership or responsibility can be confirmed when certain physical conditions have occurred (such as goods arrived at port XY) or when certain paperwork such as waybills have been recorded at certain locations. In this way, customs clearance can also be simplified and (partially) automated. The start-up Steamchain, for example, allows blockchain-based payments, IBM and Maersk have just initiated a Bockchain project for end-to-end global shipment tracking.

RPA (Robotic Process Automation) enables cost-effective automation of repetitive simple tasks (e.g., transferring data between different computer systems), eliminating human error and reducing overhead costs. For example, RPA software performs operations such as invoice processing, automatically storing information in audit trails, or automatically entering a purchase order.

11.

SUSTAINABLY GREEN

For the sake of the planet

The rather small-scale improvements towards green logistics in the past, have turned into a serious application of environmentally friendly technologies and practices in recent years. Many companies are now working on the well-known 4V strategy to make logistics more sustainable: Avoid, Shift, Reduce, Reward. For example, Gartner found the Supply Chain Top 25 to be learning from the best, working sustainably to reduce their carbon footprint, in many cases working closely with selected suppliers or customers. The key sustainability trends in logistics are:

- Reduction of the transport volumes through better planning, better demand forecasts, bundling of transports together with suppliers and customers in order to reduce the sometimes 40% empty runs of trucks. After all the activities in the direction of same day/2-h deliveries, Amazon now also offers customers in the USA the option of selecting a delivery only within the next 6 days in order to be able to bundle transports and thus reduce trips and make delivery more sustainable.

- 0-emission vehicle fleets - conversion of vehicle fleets to all-electric vehicles at logistics service providers. For example, DHL has already put a total of 20,000 all-electric Streetscooters into service in recent years and plans to add another 100,000 to its fleet in the coming years. Or Amazon, which has ordered 100,000 all-electric delivery vehicles from Rivian.

- Closed logistics loops for containers, or reusable packaging - made possible by new startups offering closed-loop packaging to industrial customers but also to end consumers. These include companies such as Loop, RePack, Returnability or The Wally Shop. Or Ikea, which is currently testing new, environmentally friendly and recyclable packaging made from renewable mushrooms (e.g. from Ecovative).

- Logistics buildings without CO2 emissions. In addition to using the roofs of logistics warehouses to produce electricity or heat by means of solar roofs, the focus is now increasingly on further optimizing and improving energy control (light, heat, cold) through intelligent IoT-based sensors.

12.

SEE AND BE SEEN

Reliable vision recognition for everything

The company identpro currently offers a sensor-based solution for scanner-free container/GLT tracking using forklifts. Here, the forklifts are equipped with various sensors, for continuous determination of the current x-/y-coordinate of the forklift in space and a height sensor on the fork to determine the z-coordinate. Each time the fork load is changed, the x-/y-/z-coordinates are written away to a database (digital twin). Thus, with a single, one-time acquisition of a GLT or a pallet (a single scan e.g. at the goods receiving area), any current localization of any pallet/GLT can be determined in real time via the digital twin. This is a working solution for scanner-free but still reliable material tracking of GLTs/pallets via forklift.

Work is currently ongoing on what is probably one of the most impactful technological trends: automated, AI camera-based container tracking without label scanning. The computer vision approach uses AI-based camera systems that continuously track and intelligently identify any movement in the respective camera's field of view from both fixed locations (e.g., mounted on the ceiling of a production floor or warehouse) or mobile locations (on AMR/route trains/stackers). The software then ensures that the movement of each container is tracked seamlessly (offered, for example, by logivations). AI support is accessed for this purpose. Even though many solutions in this area are still in pilot and test applications, this is one of the most exciting developments for the next few years that could truly revolutionize intralogistics.

AI-based label recognition is already a standard feature of the inventory drones on the market today and already works flawlessly there. The use of AI-based camera systems at goods receipt to perform a fully automated logistics check (correct goods, correct quantity, matching the order, correct label, correct packaging, and delivered free of transport damage) is only a natural further development of these camera miracle systems. This will then also bring incoming goods closer to one-touch logistics, make it even more productive, and create one of the prerequisites for automated truck unloading in the future.

Not all of the 12 fields of action are equally relevant for all companies. Priorities must be set depending on industry requirements and the Logistics 4.0 roadmap already implemented. What is certain, however, is that among the 12 fields of action that fundamentally change logistics, there are probably at least 8 with real relevance for action for each individual company. Identify your top areas of change and start implementing them as soon as possible. The topics are exciting because there have never been so many opportunities for technological innovation in logistics as there are today.

Abbreviations

- KLT / GLT Kleinladungsträger / Großladungsträger

- AMR Autonomous Mobile Robot

- NFC Near Field Communication

- WoW Warehouse on Wheels

- IoT Internet of Things

- SaaS Software as a Service

- LaaS Logistics as a Service

- KI Künstliche Intelligenz

- LTL Less than full truck-load

- API Application Programming Interface

- RFID Radio Frequency Identification Technology

- UWB Ultra-Wide-Band

- BLE Blue Tooth Low Energy

- WLAN Wireless Local Area Network

- S&OP Sales & Operations Planning

- OCR Optical Character Reading

- FTF Fahrerloses Transportfahrzeug

- RPA Robotic Process Automation

- ETA Expected Time of Arrival

Blue Color Cyborgs

Enhanced efficiency in the Warehouse 4.0

One-touch - everything else would be a waste

- Arrival truck & registration

- Drive-in and docking

- Unloading and pallet staging

- Entry, identification & booking

- Further transport to the warehouse area

- Storage / Booking

- Arrival truck & registration

- Drive-in and docking

- Unloading and pallet staging

- Recording, identification & booking

- Further transport to the warehouse area

- Putaway / Booking

- Clear process orientation

- Courage to use new technologies

- Desire and will for cross-company supply chain integration

Supply Chain Superpower

Black numbers thanks to green technology

Giant traffic jams through online shopping

The chatbot as delivery hero

- to establish new suppliers within a very short time;

- to arrive at new innovations with existing suppliers (co-innovation);

- to design new product generations together with the development department in the shortest possible time and to make them deliverable;

- to bring new talents on board with HR and to organize cross-functional cooperation within the company;

- to develop new software solutions with IT;

- to quickly integrate new acquisitions together with the M&A department.

Logistics 4.0: Guide to digital supply chains

- increasingly short term initiated, leading to an increasing volatility of demand

- faster and faster delivered - after initial tests for two-hour deliveries, the half-hourly delivery with drones is comingas next target into the realm of feasibility

- more and more transparent, since real-time tracking and tracing is standard

- cheaper, more convenient, more spontaneous and more error-free - wherebyerror tolerance and loyalty of the customers constantlydecrease

- Increasing the volume offered with fewer providers (Amazon effect): the larger the range of products offered with a few large providers, the more likely it is that customers will order previous individual orders from this provider together in the course of just one shipment / delivery. Important factors for intensifying this effect are continuous growth in the product range of the already large providers, maintaining the high level of service and, of course, intense competition. This means that this effect will only occur if there are several, but not too many, competing large providers in the future (i.e. in addition to Amazon also ebay, Otto, Zalando, ... and of course Alibaba).

- Influencing customer behaviour to choose short-cycle express deliveries (e.g. "within 2 hours" or "same-day") very consciously and only selectively in case of really urgent needs. This influence could also be achieved by the cities by increasing delivery costs (e.g. by means of a city toll) or by legal framework conditions (e.g. by increasing energy costs/taxes for transport services). Or by means of city taxes that decrease degressively over the delivery time.

- Fewer delivery trips due to collection of the goods or reduction of repeat deliveries

- Less infeed travel due to smarter infeed control

- Deliveries in different modes of transport to relieve the most congested road traffic